The RCIcast® system is used for the production of oxygen-free copper wire rods and differs from other production methods both in terms of process and mechanical design. Its advanced control system makes it easy to operate and requires minimal personnel.

In the RCIcast® system, induction furnaces with either melting-holding or melting and holding channels are specially designed according to production capacity. These furnaces can use high-purity (≥ 99.97%) copper cathodes or recycled copper scrap. It is recommended that recycled copper be as pure as possible and used in a separate melting furnace.

For the production of high-quality oxygen-free copper wire rods, copper cathodes should be used as raw material. The resulting wire rods can be used in multi-strand drawing machines for the production of enameled wires and data communication cables.

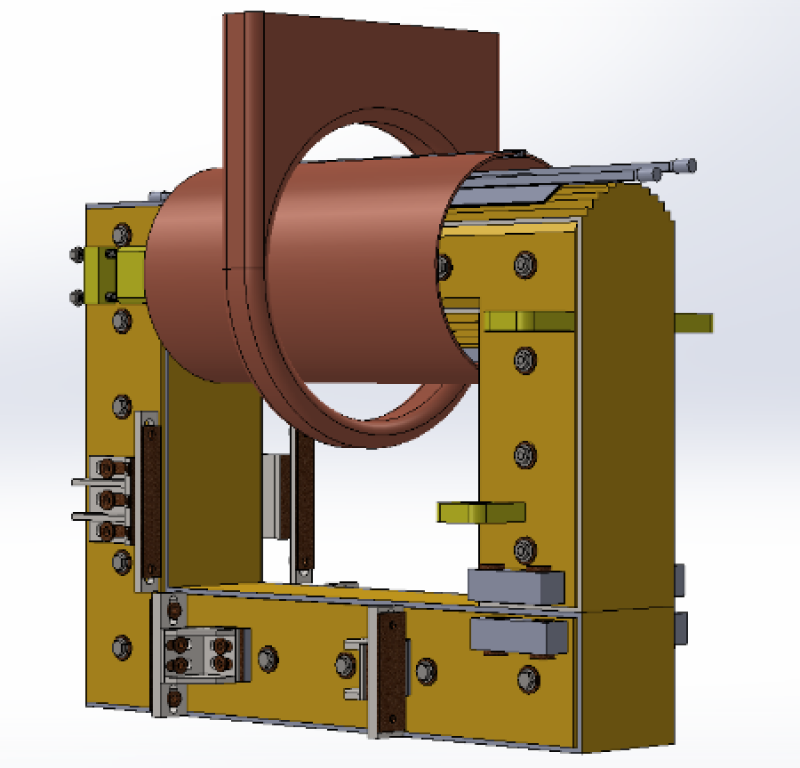

One of the key components of the RCIcast® system is the casting machine. This machine consists of multi-systems with separate cooling copper tubes for each wire rod. The coolers are mounted on the casting machine located above the melting-holding or holding furnace. A servo motor-driven pulling system lifts the product from the coolers and directs it to the coilers.

The inductors used in the channel-type induction furnaces are specially designed according to production capacity and analyzed using ANSYS MAXWELL software. The inductors are driven by IGBT-controlled electrical panels, which include a rectifier circuit, DC bus filter circuit, water-cooled DC/AC inverters, and control systems. In the DC bus filter circuit, DC chokes and compensation capacitors are used to limit total harmonic distortion (THD) and reactive power levels. IGBTs operate within the inverter circuit.

The control system monitors parameters such as current, voltage, and temperature. This ensures that the electrical cost per ton of copper wire rods produced by RCIcast® is low and the oxygen content is maintained below ≤ 20 ppm. The system produces oxygen-free wire rods without any hot rolling process, while achieving excellent electrical conductivity. The special refractories used in the furnace also provide high thermal efficiency.