Round steel bars are one of the most produced and consumed iron and steel products. In recent years, it has become common to sell round steel bars of different diameters in pieces. For this reason, the products coming out of the rolling mills should be counted completely and grouped in the desired numbers before packaging. Since the currently used steel bar counting methods are done manually by workers, it constantly slows down the production line and reduces production efficiency. Manual counting not only increases the labor cost, but also causes errors during counting.

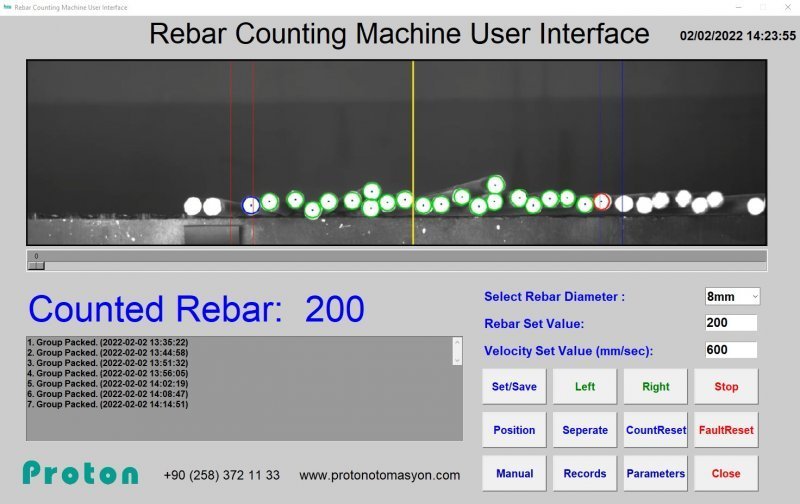

As Proton Automation, we prevent errors caused by manual counting of round steel bars with the Automatic Counting and Separation of Steel Bars of Different Diameters project with the Image Processing Method we developed within the scope of KOSGEB R&D, P&D and Innovation Support Program.

System Features

- As a result of tests carried out under suitable conditions, the count rate of round steel bars of different diameters is 99.9% with high counting accuracy.

- With the system, round steel bars of any diameter between 8 mm and 32 mm can be counted.

- The chain conveyor line speed can run smoothly up to 600mm/sec line speed. The system ensures accurate counting and separation up to 600 mm/s line speed. The devices used in the system are industrial devices and the camera communication has fiber optic transmission. The system exhibits stable performance without interference.

- With the REDES method, round steel bars are arranged on the conveyor belt and made ready for counting and separating.

- Counting errors caused by sorting are minimized by sorting with the MULSER method.

- The system has low maintenance cost as it is a non-contact measuring system.

- While the counting process is taking place, there is a counter in the interface software of the system where the number of steel bars counted can be seen.

- The system has a recording feature where the last 5 packaging photos can be seen.

- At the end of the sorting process, there is a field where the operator can see the number of packages grouped in the interface and the dates of the packages in minutes, hours, days, months and years. This information is also kept in a database on the hard disk of the industrial computer.